- Features

- Process Simulation

- Efficiency Features

Diffusion

GMPT, October 2024

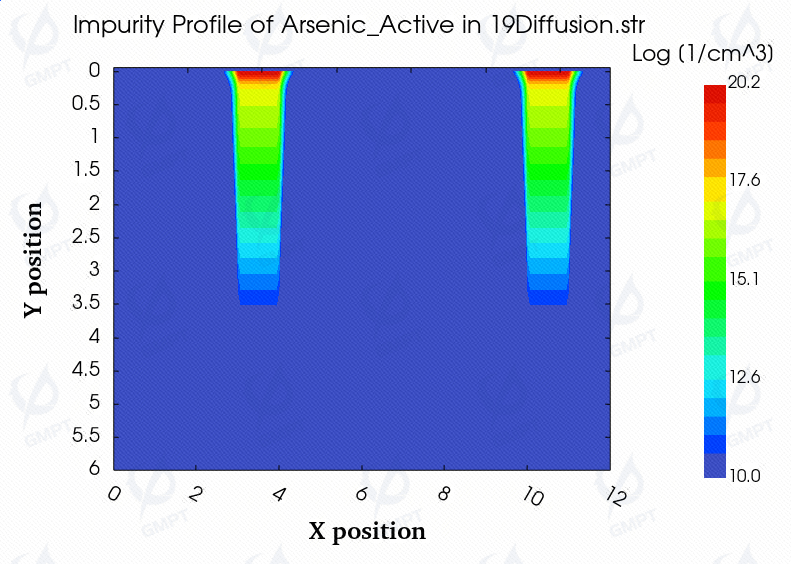

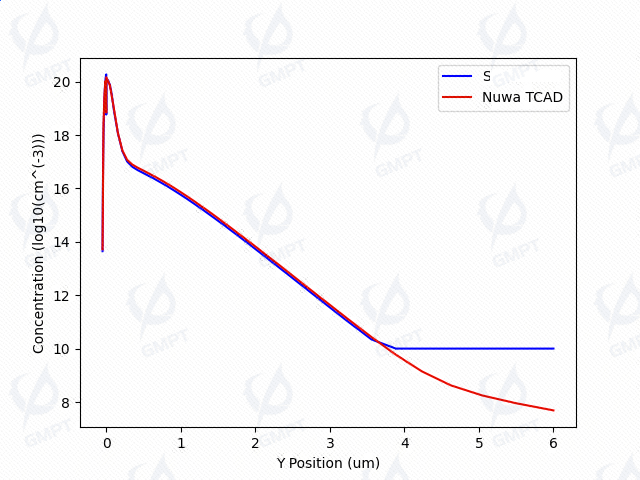

The diffusion process, through high-temperature annealing, allows for the activation of impurities within the semiconductor, the regulation of impurity concentration distribution, and the reduction of defect states. It is one of the important steps in manufacturing semiconductor devices. The diffusion process simulation function of Nuwa TCAD software can simulate the distribution of activated impurities and the total impurity distribution within the semiconductor after annealing, providing directions for process exploration.

Diffusion Process Simulation Models

The diffusion process simulation models of the Nuwa TCAD simulation tool describe the redistribution of dopants during thermal treatment, driven by concentration gradients and internal electric fields.

The diffusion models include:

- Constant model

- Fermi model

- Charged Fermi model*

- Pair model*

- Charged Pair model*

- React model*

- Charged React model*

Users can select the appropriate diffusion model according to actual conditions and simulation needs. For example, the Constant model is mainly used for dopant diffusion in oxides.

Features

- Simulates the thermal annealing process of impurities, supporting temperature changes during diffusion

- Simulates impurity diffusion processes in multi-material structures

- Supports various impurity boundary conditions, such as impurity segregation

- The material library includes diffusion models and parameters suitable for most cases, and supports user import and saving