- Features

- Process Simulation

- Efficiency Features

Oxidation

GMPT, October 2024

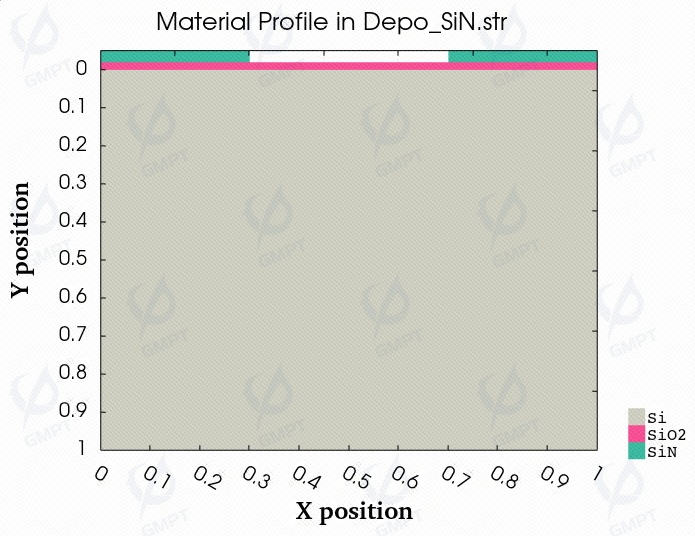

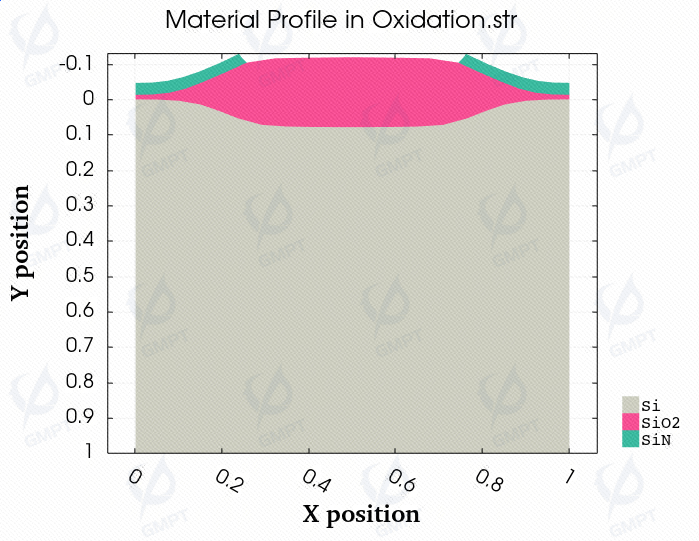

The oxidation process, through high-temperature annealing in an oxidizing gas environment, allows for the formation of an insulating or masking material, silicon dioxide, on the surface of silicon-based semiconductor materials. The morphological evolution of this oxide greatly impacts semiconductor devices, making it one of the important steps in semiconductor device manufacturing. The oxidation process simulation function of Nuwa TCAD software can simulate the oxide morphology evolution and impurity distribution within the device during the oxidation process, providing guidance for process exploration.

Oxidation Process Simulation Models

The oxidation process simulation in the Nuwa TCAD simulation tool supports simulating the thermal oxidation process of silicon. The oxidation process is divided into three steps: diffusion of oxidant from the gas-oxide interface to the silicon-oxide interface, reaction of the oxidant with silicon to form new oxide, and material movement caused by the volume expansion due to the silicon-oxide reaction.

The oxidation process simulation models of the Nuwa TCAD simulation tool include both oxidant diffusion models and stress models:

Oxidant Diffusion Models:

- One-dimensional Deal-Grove model

- One-dimensional Massoud model

- Two-dimensional diffusion model based on the Deal-Grove model

Stress Models:

- Compress model

- Viscous model

- Viscoelastic material stress calculation model

Features

- Supports setting temperature changes during the oxidation process, as well as various environmental gases, their flow rates, and pressures, which can be customized by the user as needed.

- The material library includes oxidation process simulation models and model parameters suitable for various conditions, allowing users to select and customize model parameters and import data.